Calculating the inventory results of the studied product

Companies should follow these steps when calculating the GHG impact of the studied product:

A. Choose a GWP value:

- Companies need to select a Global Warming Potential (GWP) value, which represents the impact of greenhouse gas (GHG) emissions on global warming.

- The GWP values are updated by the Intergovernmental Panel on Climate Change (IPCC) every few years. Companies can use the most recent values or other values depending on their preferences.

- Multipliers or corrections may be applied for certain emissions, such as those from aircraft transport.

B. Calculate CO2e using collected data:

- Calculate the amount of carbon dioxide equivalent (CO2e) emissions for a product based on activity data, emission factors, and the chosen GWP value.

- Different equations are used depending on whether data is collected directly or through activity data.

- If a product removes CO2 from the atmosphere during use, the removal data is considered by multiplying it by the GWP of 1 for CO2.

- When process or financial activity data is collected, the basic equation to calculate CO2 e for an input, output, or process is:(first equation)

- When direct emissions data has been collected, an emission factor is not needed and the basic equation to calculate inventory results for an input, output, or process is:(second equation)

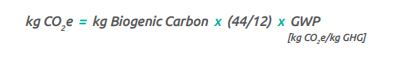

- Companies usually only know the amount of biogenic carbon contained in the material or product. To convert this to CO2 , the amount of carbon is multiplied by the ratio of molecular weights of CO2 (44) and carbon (12), respectively. CO2 removal data, like direct emissions data, does not need to be multiplied by an emission factor and can simply be multiplied by the GWP of 1 for CO2 .(third equation)

C. Calculate total inventory results (CO2e/unit of analysis):

- Ensure all results are on the same reference flow basis (e.g., per kg of product).

- Sum the CO2e emissions and removals per unit of analysis to get the total CO2e entering the atmosphere due to the product’s function.

- Include land-use change impacts if attributable to the product.

- The following components make up the total inventory results:

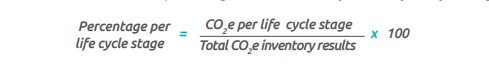

D. Calculate percentage of total inventory results by life cycle stage:

- Determine the percentage of total inventory results for each life cycle stage.

- Land-use change impacts and removals are typically attributed to specific stages.

- Virgin material displacement factor is reported separately to avoid a negative percent impact in the end-of-life stage.

- The following equation is used to determine the percentage of total inventory results by life cycle stage:

E. Separate reporting of biogenic and non-biogenic emissions and removals and land-use change impacts, when applicable:

- Report biogenic emissions, non-biogenic emissions, biogenic removals, and non-biogenic removals separately for transparency.

- If unsure, consider emissions as non-biogenic.

- Land-use change impacts are reported separately.

- Biogenic emissions include CO2 , CH4 , and N2 O that are produced as a result of the combustion and/or degradation of biogenic materials, wastewater treatment, and a variety of biological sources in soil and water. For example, if paper degrades in a landfill, the CO2 and CH4 emitted would be classified as biogenic emissions.

- Non-biogenic emissions include all GHG emissions from non-biogenic (e.g., fossil-based) materials.

F. Calculate cradle-to-gate and gate-to-gate inventory results separately:

- Provide insights into emissions and removals under the control of the reporting company.

- Consider confidentiality concerns when reporting gate-to-gate results.

- Cradle-to-gate results cover the entire life cycle, while gate-to-gate focuses on specific stages.

Offsets and avoided emissions

Offsets: Companies often buy emission credits, known as offsets, to compensate for the greenhouse gas emissions produced by their products.

They do this for two main reasons:

- Meeting Reduction Goals: Companies might have goals to reduce their overall emissions. If they can’t achieve these goals through direct reductions alone, they purchase offsets to make up the difference.

- Claiming Carbon Neutrality: Some companies want to label their products as carbon neutral. To do this, they buy offsets to balance out the emissions generated by their products.

Avoided Emissions:

Avoided emissions are reductions in emissions indirectly caused by market responses to a product or process during its life cycle. For example, if a company makes energy-efficient appliances, it may assume that these appliances replace less efficient ones in the market, leading to emission reductions.

However, this standard doesn’t allow companies to subtract avoided emissions from the total inventory results. Instead, companies can report avoided emissions separately. Avoided emissions are often calculated using a consequential approach, considering how emissions might change due to shifts in demand.

It’s important to note that if there are indirect impacts, such as changes in land use, caused by market responses to the product or its life cycle, these should be reported separately.

Notable Points:

In life cycle assessment (LCA), the term “avoided emissions” might refer to different things like system expansion or emission reductions within a product’s boundary. These cases are not considered as avoided emissions per this standard, but other reporting requirements still apply.