Introduction

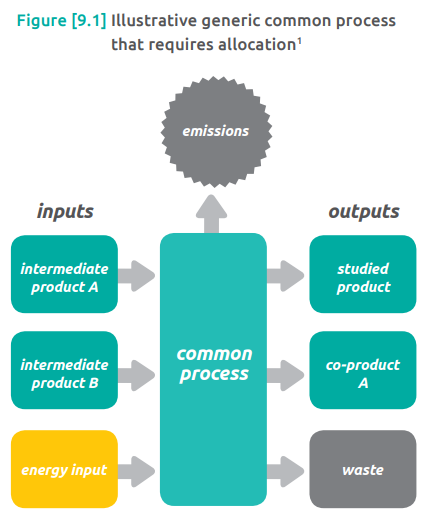

Imagine you’re tracking the environmental impact of making a product, like a smartphone. When creating a product, there are certain steps that involve shared processes, where multiple products contribute or benefit. For example, the electricity used to manufacture the phone might also be used for other products.

Now, the problem is that you can’t always measure the environmental impact for each individual product involved in these shared processes. So, if you’re trying to figure out how much greenhouse gas (GHG) emissions come from making the smartphone, but some of the processes are shared with other products, you need a way to divide or allocate these emissions accurately among the different products.

This dividing or allocating process is called “allocation.” It’s a crucial part of keeping track of the environmental impact of a product. There are two main types of products in these shared processes:

- Studied Product: This is the main product you’re interested in, like the smartphone in our example. You want to know how much environmental impact it has.

- Co-products: These are other products that are part of the shared processes. They might not be the main focus, but they contribute to the overall impact.

Inputs to the shared processes can be things like services, materials, or energy used, and outputs can be intermediate or final products, energy outputs, or waste.

There are different ways to allocate these shared emissions and provides guidance for companies to choose the best method for their product tracking. It’s important because accurately attributing emissions to the studied product helps maintain the quality of the environmental impact assessment.

While the examples focus on emissions, the same principles apply to removal of emissions (like carbon capture or reforestation) and provides guidance on how to choose between allocation methods.

Requirements

- Companies shall allocate emissions and removals to accurately reflect the contributions of the studied product and co-product(s) to the total emissions and removals of the common process.

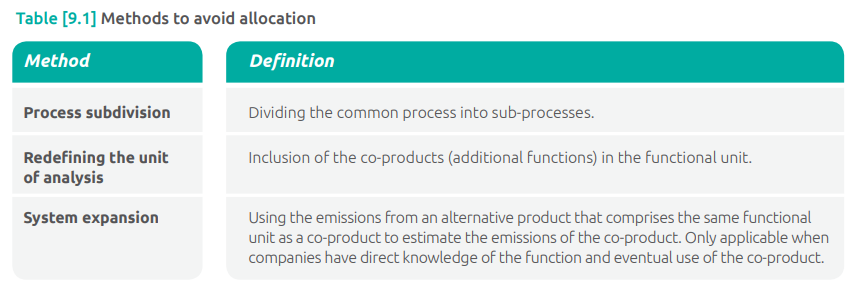

- Companies shall avoid allocation wherever possible by using process subdivision, redefining the functional unit, or using system expansion.

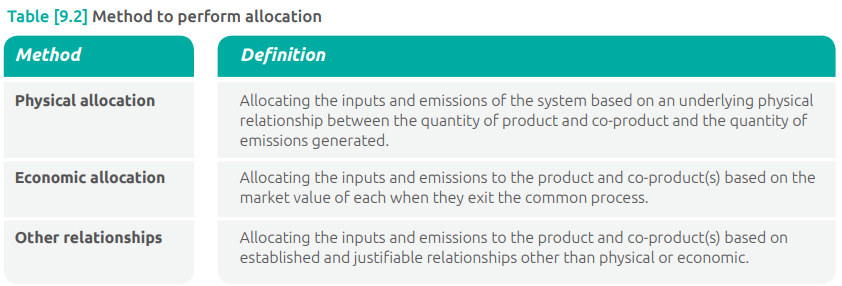

- If allocation is unavoidable, companies shall allocate emissions and removals based on the underlying physical relationships between the studied product and co-product(s). When physical relationships alone cannot be established or used as the basis for allocation, companies shall select either economic allocation or another allocation method that reflects other relationships between the studied product and co-product(s).

- Companies shall apply the same allocation methods to similar inputs and outputs within the product’s life cycle.

- For allocation due to recycling, companies shall use either the closed loop approximation method or the recycled content method as defined by this standard.

- Companies shall disclose and justify the methods used to avoid allocation or perform allocation due to co-products or recycling. When using the closed loop approximation method, companies shall report displaced emissions and removals separately from the studied product’s end-of-life stage inventory.

- Allocation and Principles:

- Allocation: It’s like dividing the environmental impact among the main product and the other products involved in making it.

- Completeness and Accuracy: Companies need to accurately share the environmental impacts among the main product and co-products to get the full picture.

- Waste: If a co-product doesn’t have any value (like it’s just waste), no environmental impact is allocated to it.

- Avoiding Allocation:

- Process Subdivision: Dividing the production process into smaller parts to better track environmental impacts.

- Redefining Functional Unit: Adjusting the basic unit used for measurement to make tracking easier.

- System Expansion: Expanding the system boundaries to include more processes and inputs, providing a more comprehensive view.

- Consistency and Recycling:

- Consistency: Using the same allocation methods for similar things in the product’s life cycle, like inputs and outputs.

- Recycling: Handling the allocation of emissions when products are recycled. It’s tricky because recycling processes are often shared among different product life cycles.

- Methods for Recycling Allocation:

- Closed Loop Approximation Method: It considers the impact of recycling on acquiring new materials.

- Recycled Content Method: It allocates emissions to the life cycle using the recycled material.

- Alternative Methods for Recycling:

- If the above methods don’t work, companies can use another method if it meets certain conditions (like accurately representing emissions and being disclosed in reports).

- Reporting:

- Companies must disclose and explain the methods they use for allocation or avoiding allocation.

- Specific details about the choice of methods and factors should be reported, explaining why they accurately show the product’s contribution to environmental impacts.

- Closed Loop Approximation Method:

- When using this method, there’s a factor (virgin material displacement factor) that needs to be subtracted from the total results. However, this displacement factor is reported separately to avoid confusion.