Guidance

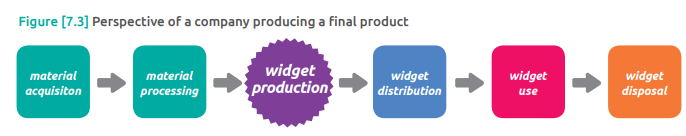

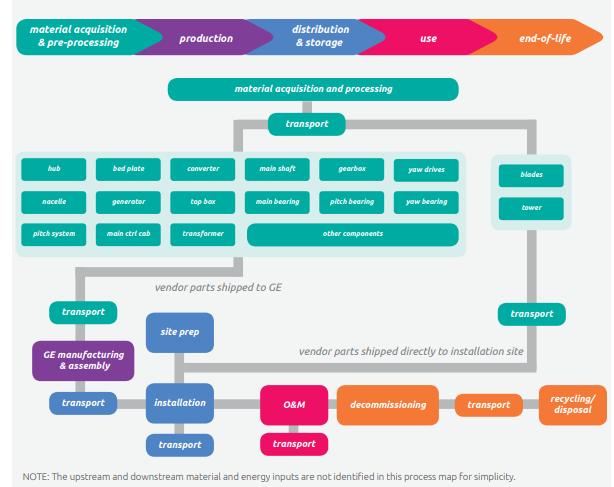

1. Defining life cycle stages and identifying attributable processes

- Material Acquisition and Preprocessing:

- What happens: This stage begins when the raw materials are taken from nature and continues until these materials reach the production facility where the final product is made. It includes processes like extracting resources, processing recycled materials, and transporting these materials to the production site.

- Examples of processes: Mining, extracting materials or fossil fuels, photosynthesis for biogenic materials, cultivating and harvesting trees or crops, applying fertilizer, and various preprocessing activities like chipping wood or cleaning coal.

- Production:

- What happens: This stage starts when the components needed for the product enter the production site and ends when the finished product leaves. It involves the actual manufacturing processes, assembling components, packaging, and handling waste generated during production.

- Examples of processes: Physical or chemical processing, manufacturing, transport of semi-finished products between manufacturing processes, assembly of material components, packaging, and treatment of waste.

- Product Distribution and Storage:

- What happens: This stage begins when the finished product leaves the production facility and continues until the consumer takes possession of the product. It includes various distribution and storage activities such as transportation, receipt at distribution centers, heating/refrigeration, and shipping.

- Examples of processes: Operations at distribution centers or retail locations, receipt, put away, heating/refrigeration, shipping transportation, and transportation between storage locations.

- Product Use:

- What happens: This stage starts when the consumer gets the product and ends when the product is discarded for waste treatment. The impact in this stage depends on how the product is used. For products using energy, the use stage may have the largest environmental impact.

- Examples of processes: Transportation to the use location, refrigeration at the use location, preparation for use (e.g., microwaving), actual use (e.g., power consumption), and any repair or maintenance during usage.

- End-of-life:

- What happens: This stage starts when the consumer discards the product and ends when the product is treated, either returned to nature (e.g., incineration) or used in another product’s life cycle (e.g., recycling). The main concern here is how the product is handled after use.

- Examples of processes: Collection and transport of discarded products, waste management, dismantling of components, shredding and sorting, incineration, sorting of bottom ash, and landfilling.

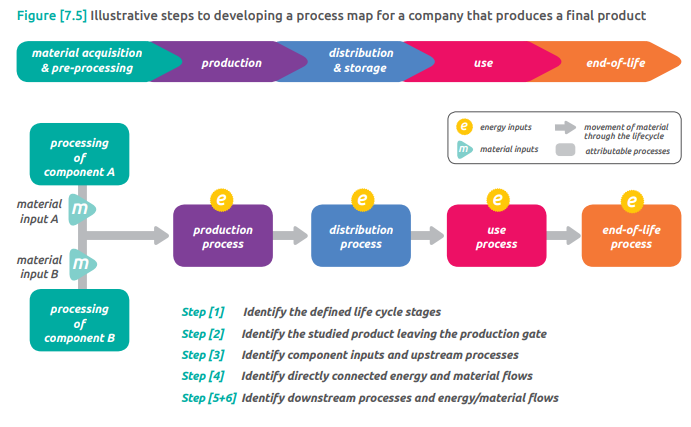

2. Developing a process map

A process map is like a roadmap that helps a company understand and track all the steps involved in making a product or providing a service. This passage outlines the steps companies can follow to create a process map, particularly for understanding the environmental impact of a product from its creation to its end.

Let’s break down the steps:

- Identify Life Cycle Stages:

- What to do: Start by recognizing the different stages a product goes through from the extraction of materials to its end-of-life or production (depending on the type of inventory).

- Why: This helps set the boundaries for the analysis, making sure all relevant stages are considered.

- Identify Finish Point:

- What to do: Locate where the product is considered finished and leaves the company’s control or gate.

- Why: This helps define the endpoint for the environmental assessment.

- Identify Inputs and Processes:

- What to do: Figure out all the components and the steps needed to create and transport the finished product, placing them in the right life cycle stage.

- Why: This step lays the foundation for understanding how the product is made and what goes into its production.

- Identify Flows and Impacts:

- What to do: Look at the energy and material flows involved in each step, considering both inputs (things that go in, like fertilizers or lubricants) and outputs (waste and co-products).

- Why: Understanding these flows helps in calculating the environmental impact at each stage of the product’s life.

- For Cradle-to-Grave Inventories:

- What to do: If you’re considering the entire life cycle of the product (from creation to end-of-life), identify the steps and flows involved in distributing, storing, and using the product.

- Why: This broadens the assessment beyond just production, considering the impacts of the product throughout its entire life.

- Identify End-of-Life Inputs:

- What to do: Specifically for cradle-to-grave inventories, recognize the inputs needed for the end-of-life stage (how the product is disposed of or recycled).

- Why: This ensures that the environmental impact of disposing of the product is considered.

3. Identifying attributable processes in the use and end-of-life stages

This explains how companies deal with challenges in understanding and measuring the environmental impact of a product during its use and disposal stages. Here’s a detailed breakdown:

- Assumptions in Process Mapping:

- What happens: When creating a process map, companies often have to make assumptions about the specific processes involved in creating, distributing, and selling their product.

- Why: This is because the exact details of how a product is used can vary a lot between users, making it challenging for companies to pinpoint the exact processes during the use stage.

- Difficulty in Determining Use Stage Processes:

- What happens: Figuring out the processes involved during the use stage (how customers use the product) is particularly tricky because different users may use the product in different ways.

- Why: The passage suggests that because the “use profile” can vary, companies find it difficult to precisely determine the processes that contribute to the product’s environmental impact during its use.

- Functional Unit Definition:

- What happens: Companies start by looking at the functional unit definition for the product. This includes understanding the product’s function, the duration it provides its service, and the quality of that service.

- Why: This helps in identifying the use profile processes by aligning them with the intended function and service life of the product.

- Assuming a Use Profile:

- What happens: Since the service life may not perfectly match the use profile, companies make an assumption about the profile that most accurately represents how their product is typically used. This aligns with the approach set by standards and data collection requirements.

- Why: This ensures that the environmental assessment is as accurate as possible, even if the exact use of the product can vary.

- Consideration of Geographic Variation:

- What happens: The passage notes that processes during the use and end-of-life stages can differ significantly between locations. Companies may use global averages, but focusing on specific regions or countries can offer more accurate insights into the environmental impacts.

- Why: Different regions might have different waste management practices or energy sources, so considering geographic variation improves the accuracy of the assessment.

- Scenario Uncertainty and Sensitivity Analysis:

- What happens: When there are multiple possible use or end-of-life profiles, companies can conduct a sensitivity analysis to understand how each scenario might impact the total environmental inventory results.

- Why: This helps in assessing the uncertainty and understanding how different use scenarios (e.g., storing food in the freezer for different durations) affect the overall environmental impact.

4. Estimating to determine insignificance

This passage is discussing how a company can determine if certain processes or emissions are so small that they can be considered insignificant in the context of environmental impact assessments. Let’s break it down:

- Determining Insignificance:

- What happens: Companies want to figure out if certain processes or emissions are so tiny that they can be considered insignificant in terms of their impact on the environment.

- How: The company estimates the emissions from a process using the upper limit assumptions (considering the most conservative case). They then check if, based on criteria like mass, energy, volume, and greenhouse gas (GHG) relevance, the process is indeed insignificant.

- Establishing a Definition of Insignificance:

- What happens: To decide if something is insignificant, a company needs to set a definition of what “insignificant” means in their specific context.

- How: The definition might include a rule of thumb threshold. For instance, the rule could be that material or energy flows are considered insignificant if they contribute less than one percent of the total mass, energy, or volume, and if the estimated GHG impact is also less than a certain threshold.

- Example of Rule of Thumb:

- What happens: The passage gives an example of a rule of thumb. It suggests that if a material input contributes only 0.5 grams to a total of 100 grams for a product, and even if that material is environmentally impactful, it may be considered insignificant if it doesn’t exceed one percent of the total mass or environmental impact.

- Why: This rule helps companies set practical limits for what they consider insignificant based on their environmental goals.

- Reflecting Business Goals:

- What happens: The definition of insignificance should align with the company’s business goals for conducting the environmental inventory.

- Why: This ensures that the determination of what is considered insignificant is in line with the company’s broader objectives and strategies.

- Disclosure and Justification:

- What happens: Companies are required to disclose and justify any exclusions of processes they deem insignificant in their inventory report.

- Why: This transparency is necessary to explain to stakeholders and regulatory bodies why certain processes or emissions were excluded from the assessment.

5. Non-attributable processes

This explains that when companies are assessing the environmental impact of a product, they generally focus on processes directly related to that product. However, there are situations where certain processes, though not directly linked to the product, might still need to be considered. Let’s break it down:

- Non-Attributable Processes:

- What happens: Non-attributable processes are those not directly connected to the product being studied. Companies are not obligated to include them in their assessment boundary (the scope of what they’re looking at).

- Why: This is because the primary focus is on the processes directly related to the studied product to make the assessment more manageable.

- Inclusion of Non-Attributable Processes:

- What happens: Companies may choose to include non-attributable processes in their inventory under certain circumstances.

- When: This inclusion might happen if these non-attributable processes cannot be separated from the data related to the studied product or if the company determines that these processes are relevant to the environmental impact of the studied product.

- Determining Relevance:

- What happens: Relevance, or the importance of including non-attributable processes, is determined by the company. Various factors can influence this decision.

- Factors: The company might consider its business goals, potential for environmental impact reduction, adherence to product rules or sector guidance, and the relative impact of these non-attributable processes compared to the rest of the inventory.

- Examples of Relevant Non-Attributable Processes:

- What happens: Certain non-attributable processes, such as capital goods and infrastructure, might be considered relevant to some products.

- Why: For instance, renewable energy generation like hydroelectric or wind power requires significant capital infrastructure, which can have a substantial greenhouse gas (GHG) impact. In such cases, these non-attributable processes might be included in the assessment.

- Corporate Activities as Relevant Processes:

- What happens: Corporate activities, which are non-attributable processes, might also be seen as relevant in some cases.

- Why: If a company identifies its own activities as having a substantial impact and sees potential for significant reduction, it might choose to include these non-attributable processes in the assessment.

6. Time period

This explains how the total time period for assessing the environmental impact of a product is influenced by its use and what happens at the end of its life.

- Use-Stage Time Period:

- What happens: The time period for assessing the environmental impact during the use stage is determined by how long the product is expected to provide its service.

- Example: If a laptop is designed to function for 5,000 computing hours, eight hours a day, five days a week, the use-stage time period would be 2.4 years.

- End-of-Life Time Period:

- What happens: The time period for the end-of-life stage is based on how the product is disposed of and how long it takes for the product’s carbon to return to nature.

- Example: Waste treatment methods vary, and waste that is incinerated has a much shorter time period compared to waste that is disposed of in a landfill. The time period also depends on when the carbon in the product returns to the atmosphere.

- Variation in End-of-Life Time Period:

- What happens: The end-of-life time period can vary significantly based on the assumed waste treatment and the geographic location.

- Example: Waste incineration has a shorter time period compared to landfill disposal. Some waste treatment methods may not release all the carbon into the atmosphere. For instance, lignin, a component of wood, does not degrade under certain conditions.

- Disclosure and Justification:

- What happens: When a company knows that not all of a product’s carbon returns to the atmosphere during waste treatment, it is required to disclose and justify this in the inventory report.

- Example: If a material in the product, like lignin in wood, doesn’t release carbon during waste treatment, the company must explain this in the report.

- Carbon Storage Clarification:

- What happens: The passage emphasizes that a company cannot assume that carbon is stored in a product simply by shortening the end-of-life time period. Carbon storage must be known and justified.

- Example: A company can’t assign a short end-of-life time period to a product that actually degrades over a longer period. It needs to be certain that the carbon is stored indefinitely due to waste treatment.

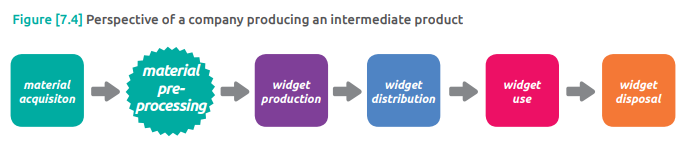

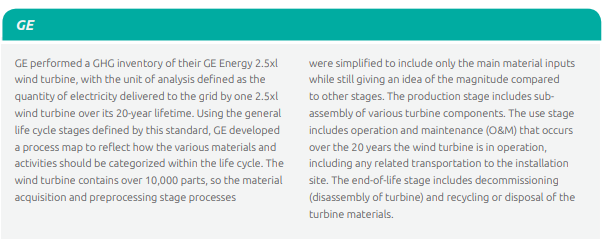

7. Cradle-to-gate inventories

This explains how companies handle the assessment of environmental impact for intermediate products – products that are used to make other final products. There are two scenarios to consider:

- Known Use Profiles:

- What happens: If the company making the intermediate product knows exactly how the final product will be used, they should conduct a complete life cycle assessment (cradle-to-grave) for the intermediate product. This means considering all stages, including distribution, retail, use, and end-of-life.

- Advantage: This approach provides more opportunities for reducing environmental impact and offers stakeholders a complete understanding of the intermediate product’s life cycle.

- Collaboration: Companies might collaborate with the producer of the final product, leveraging their expertise and data for a more accurate assessment.

- Unknown Use Profiles:

- What happens: If the use profile of the final product is unknown, the company making the intermediate product may choose to perform a cradle-to-grave inventory by assuming a representative or average use profile. Alternatively, they may opt for a cradle-to-gate inventory.

- Transparency Requirement: Transparency is crucial, especially if downstream customers of the intermediate product want to use the data for a cradle-to-grave inventory of their final product. The company must clearly disclose and justify the use of a cradle-to-gate boundary, explaining why the full life cycle isn’t considered.

- Preserving Continuity: A cradle-to-gate inventory, as per the standard, does not include the use and end-of-life stages of the final product. This is to maintain the continuous nature of the life cycle approach and prevent selective reporting that excludes GHG-intensive stages while including less impactful stages.

- Additional End-of-Life Information:

- What happens: Even in a cradle-to-gate inventory, the company producing the intermediate product may have useful information about end-of-life processes, such as recycling rates or time periods.

- Inclusion in Report: While this information can be included in the report, it must be clearly separated from the main inventory results and the process map.