This blog is like a roadmap that guides a company on how to collect and handle data for their greenhouse gas (GHG) inventory. It’s not just about gathering the data but also making sure it’s good quality and following specific rules. This plan helps from the very beginning of collecting data all the way to when the final report is ready.

Why It's Important

Having a data management plan is super useful. It helps a company keep everything organized and see how well they’re doing with their data. It’s like having a checklist for a big project.

Similar to Other Plans

Sometimes, a company might already have plans for collecting different kinds of data or following certain rules (like ISO standards). If possible, they can use some of those plans for their GHG data too, so they don’t have to do everything from scratch.

Helping with Assurance

The data management plan can also be a helpful tool when someone (internal or external) needs to check that everything is done correctly. It’s like providing a clear guide for them to make sure the company’s data is accurate.

Two Parts: QC and QA

The plan is usually divided into two parts. One is about Quality Control (QC), which is all about making sure the data is accurate and reliable. The other is Quality Assurance (QA), which is like double-checking that the whole process of collecting data is done correctly. These two parts are like the detectives who ensure the data is good and the process is solid.

1. Quality control

This is like having a system or set of regular activities to check and manage the quality of the data used for the greenhouse gas (GHG) inventory. The goal is to make sure that the data is accurate and reliable. QC helps in avoiding mistakes or missing information, making sure everything is consistent, and making it easier for both internal and external reviews of the inventory.

- Preventing Errors and Omissions: One of the main jobs of QC is to spot and fix mistakes or things that are left out (omissions) in the data. It’s like having a detective who looks for errors and missing pieces in the data puzzle.

- Ensuring Consistency: QC also makes sure that everything is done the same way, so the data is consistent. Think of it like following a recipe where you measure ingredients in the same units every time to make sure your dish tastes the same.

- Helping with Reviews and Assurance: QC makes it easier for people inside and outside the company to look at the data and be sure it’s good. It’s like preparing your work so that it’s easy for your teacher to check and give you a good grade.

2. Quality assurance

This part of the plan is like a final check to make sure the greenhouse gas (GHG) inventory is good quality. It involves two main things: peer review and audits.

- Peer Review: This is like having a friend look over your homework to see if it’s done correctly. In the case of GHG inventory, it means having someone who wasn’t involved in making the inventory check the methods and results to catch any errors or biases. They don’t dive deep into the data itself but make sure the process used to create the inventory is solid.

- Audit: An audit is like a professional inspection. It’s a more thorough check to see if the inventory follows all the quality control rules in the data management plan. Audits are done by someone who wasn’t part of the inventory development.

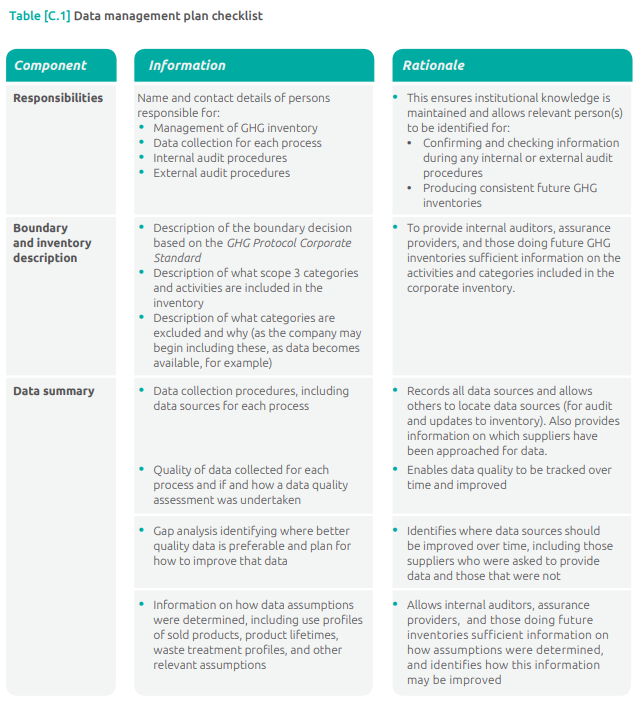

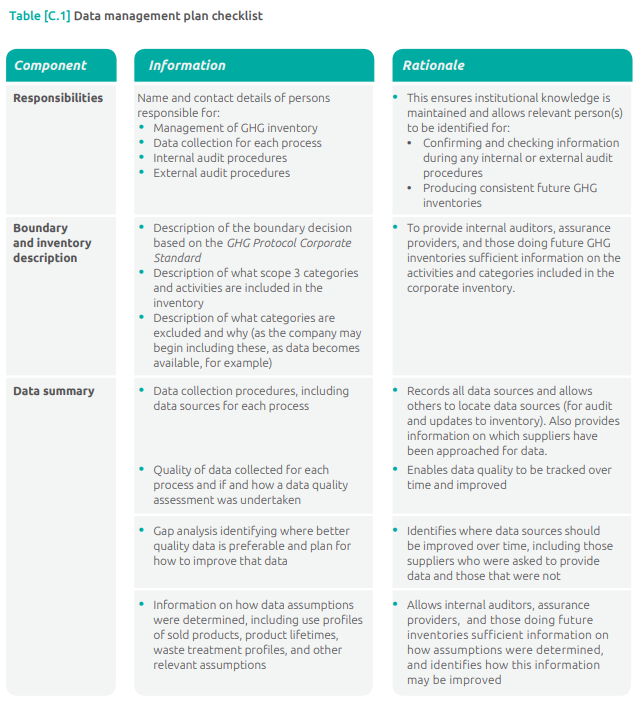

- What Should Be in the Plan: The plan should include details about what’s in the GHG inventory, who’s responsible for collecting data, how the data is collected, where it comes from, how it’s calculated, and much more. It also says how long the data should be kept and how it’s stored and backed up.

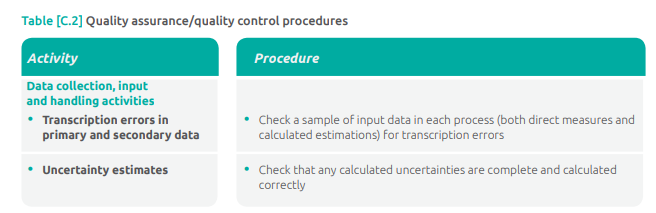

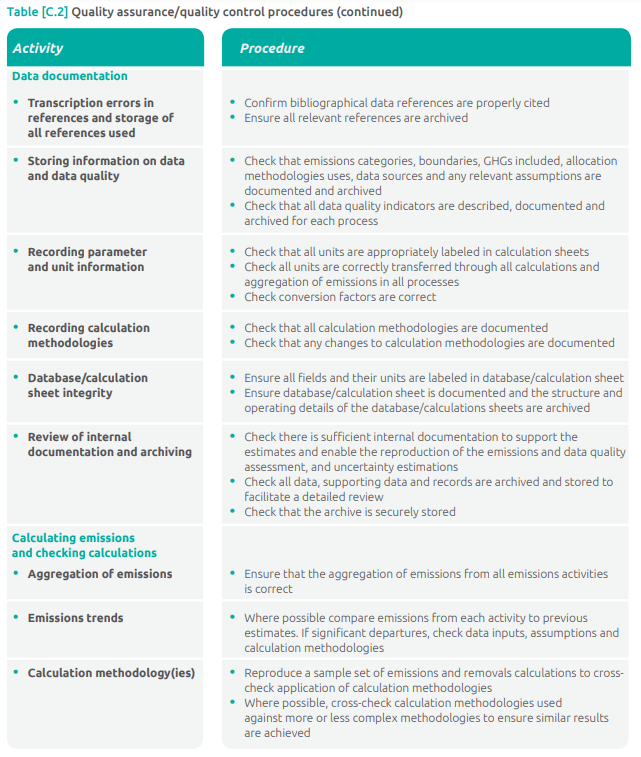

- QA/QC Procedures: This part of the plan also includes all the methods and checks (QA/QC procedures) for collecting and handling data. It’s like having a recipe for data management that covers quality control and quality assurance.

Creating a data management plan

To develop a data management plan, the following steps should be undertaken and documented.

Assign a GHG Quality Person/Team: Choose someone or a team responsible for making sure the plan is followed. They are in charge of maintaining the plan, improving data quality, and coordinating with others like suppliers, reporting programs, and auditors.

Create the Data Management Plan: This is like making a detailed recipe for how to manage data for the greenhouse gas (GHG) inventory. It should cover everything, like what’s in the inventory, who collects the data, how it’s collected, where it comes from, and how it’s calculated. Start this plan before collecting data to make sure you document everything as you go. It will change over time as you learn and improve.

Do General Data Checks: Think of this as a general check-up for the data. Look at all parts of the data to make sure it’s good quality, and also check how it’s handled and documented.

Do Specific Data Checks: Now, focus on more detailed checks for the data that’s really important in the inventory or where there might be doubts. It’s like giving special attention to the ingredients that are most important in a recipe.

Review and Report the Inventory: Look over the final inventory and the report that goes with it. This is like tasting the dish you cooked to make sure it’s just right. This step is done both internally within your company and as part of the assurance process, which is like getting feedback from a food critic.

Create Feedback Loops: Feedback loops are like ways to learn from your mistakes and keep improving. They help make the inventory better over time.

Set Up Data Recording and Archiving: This is like organizing your recipe collection. You need a way to keep track of all the data you used and store it safely. It’s also about having a system to easily find and use this data in the future.