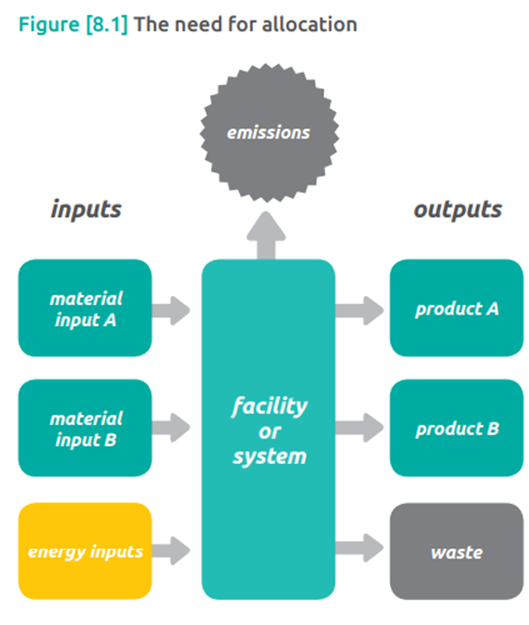

Allocation is a process that companies use to divide or share the greenhouse gas emissions (GHG) produced by a single facility or system among the different products or outputs it generates. It’s like distributing the responsibility for emissions among various things the facility produces.

Companies need to do this allocation when:

- A single facility or system makes many different products or outputs, but the emissions are only measured for the entire facility.

- For instance, a factory produces various items, but the emissions data is collected for the entire factory, not for each item.

- A company buys components or materials from a supplier that makes many different things for different customers, and the supplier’s emissions data needs to be divided among those products to show each customer how much emissions are linked to the specific products they purchase.

When allocation is not needed:

- When a facility or system makes only one product or output, so there’s no need to divide emissions because there’s only one thing being produced.

- When the emissions for each output are measured separately.

- If a factory measures emissions for each product it makes individually, there’s no need to allocate.

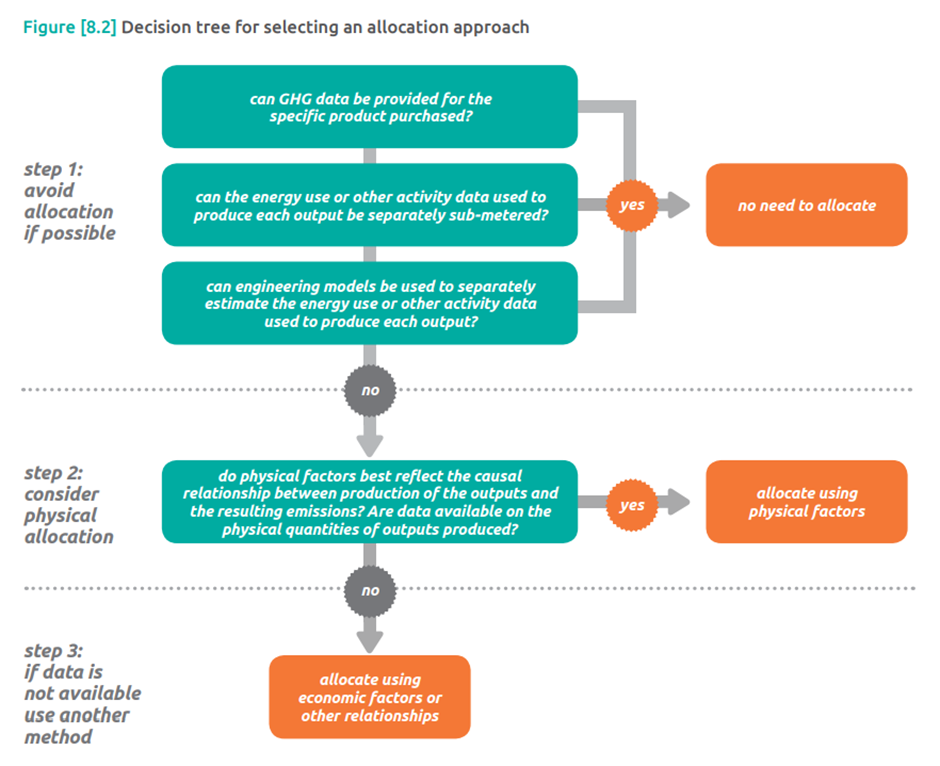

Avoid or minimize allocation if possible

When companies are trying to figure out how much greenhouse gas emissions their business activities create (like making products or running operations), they want to be as accurate as possible. They use something called “allocation” to divide these emissions among different things they do. However, allocation can be tricky and not very accurate, especially when a company’s activities make a lot of different products that have very different impacts on the environment.

For instance, let’s say a supplier makes 20 different products, but they only sell one of them to another company. If this company uses allocation to figure out the emissions of the supplier, it might not be accurate. This is because the emissions of the one product they buy might be very different from the average emissions of all 20 products made by the supplier. So, using allocation in this case wouldn’t give a reliable picture of the emissions.

To make things more accurate and avoid allocation, companies should try to get better and more detailed information in these ways:

- Get specific information about the emissions for the exact product they’re interested in. This helps them avoid making guesses by using the average of everything.

- Measure energy use and other activities at a very detailed level, like for each production line or specific process.

- Use special tools and models that help estimate emissions for each individual product, so they don’t have to rely on averages.

The idea is to avoid allocation as much as possible because it can make the emissions calculations less accurate. Instead, companies should aim for precise data to better understand and reduce their environmental impact.

Allocation methods

1. Allocation When It’s Necessary:

- Allocation means splitting up or sharing the responsibility for greenhouse gas emissions among different things a company does.

- Sometimes, companies have to use allocation because it’s hard to measure emissions for each thing separately.

- For example, if a supplier makes 20 different products but only sells one to a company, dividing emissions by allocation can be inaccurate.

- Companies should only use allocation when they don’t have more accurate data.

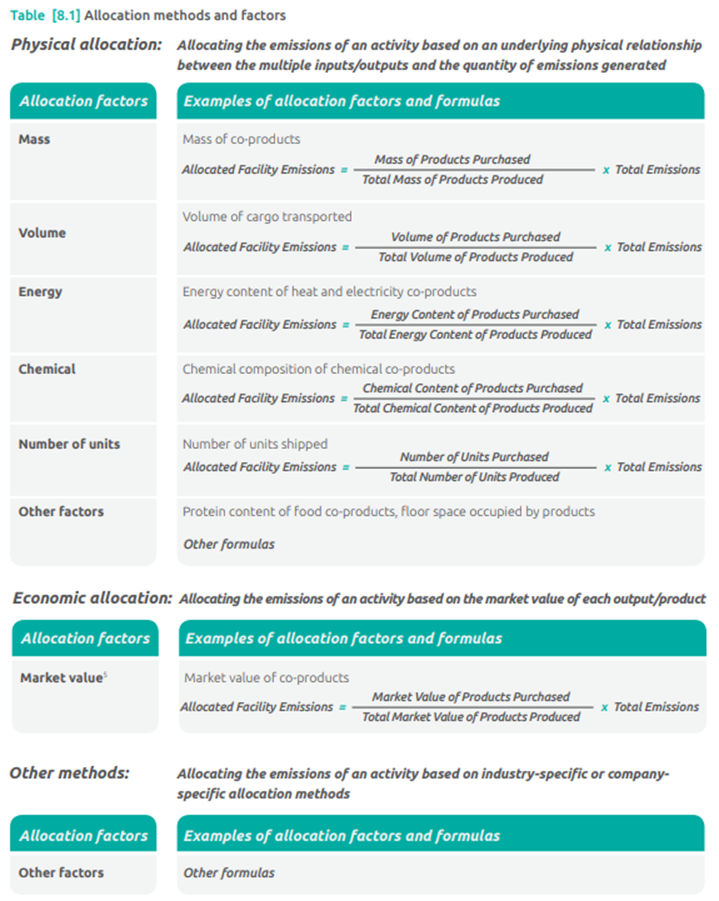

2. Choosing the Right Allocation Method:

- If a company has to use allocation, they should first find out how much total emissions their facility or system produces.

- Then, they need to pick the best method to divide these emissions among different things.

- There are different methods and factors for allocation

- A decision tree can help companies decide if they need allocation and which method to use.

- The best allocation method depends on the situation and should:

- Show the link between making things and emissions clearly.

- Give the most accurate and trustworthy emissions estimates.

- Help with decision-making and reducing greenhouse gases.

- Follow important principles like being relevant, accurate, complete, consistent, and transparent.

- Different methods can lead to different results, so companies should check different options before choosing one (like a sensitivity analysis).

- A company might use a mix of methods for various activities, but within one facility or system, they should use one consistent method. The total of the allocated emissions should equal 100 percent of the system’s emissions.

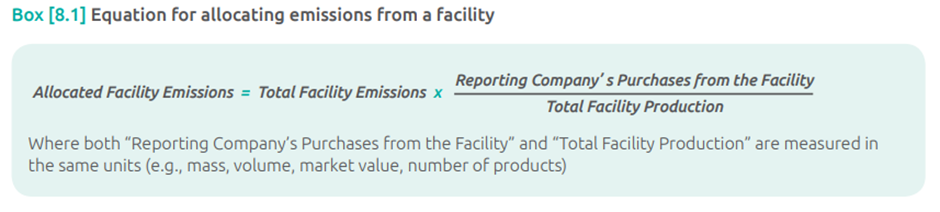

3. How to Allocate Emissions:

- To allocate emissions from a facility, multiply the total emissions by the purchases made by the reporting company compared to the total production.

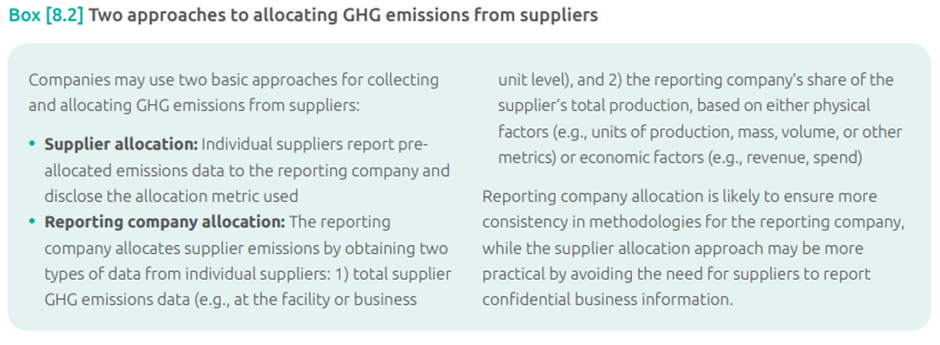

- Either the reporting company or its suppliers can divide emissions if the company purchases something from a supplier.

4. Waste and Allocation:

- When a company makes waste during production, like in categories 1, 2, or 10, no emissions from the facility should be assigned to the waste.

- Instead, emissions from the facility should be shared among other outputs.

- Waste is something a company doesn’t make money from, and they often have to pay to get rid of it. If waste becomes useful and can be sold, it’s not considered waste anymore and should be treated like other products.

5. Exceptions for Waste:

- The above rules don’t apply to category 5 (Waste generated in operations) or category 12 (End-of-life treatment of sold products). Companies should account for all emissions related to waste in these categories.