Guidance for selecting data

Data Types for Calculating Scope 3 Emissions:

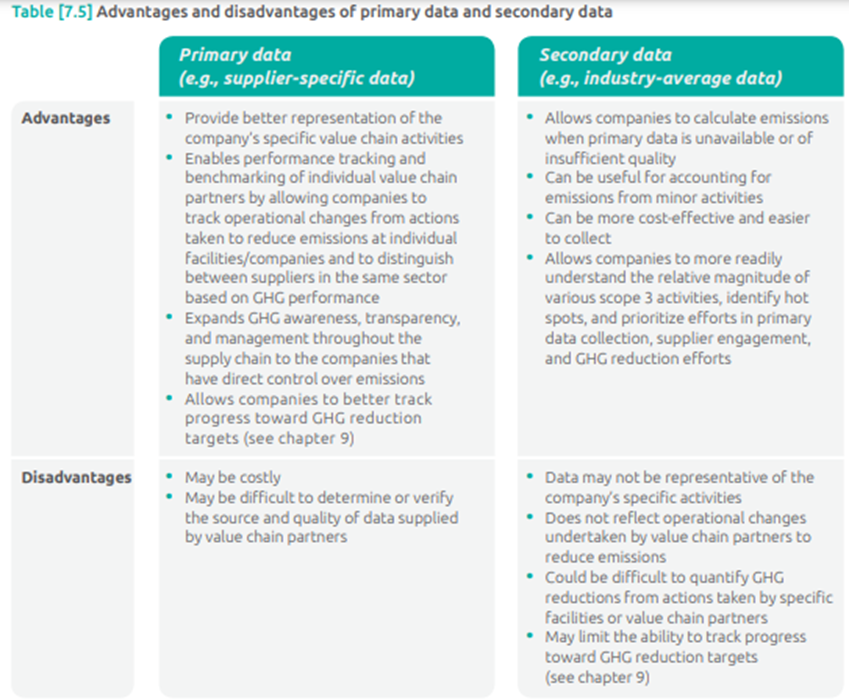

Companies use two main types of data for scope 3 emissions: primary data and secondary data.

Primary Data:

- This data comes directly from your suppliers or value chain partners.

- It’s specific to particular activities in your value chain.

- For instance, data about fuel consumption from your suppliers for shipping activities is primary data.

Secondary Data:

- This data doesn’t come directly from your partners but is gathered from various sources like industry reports, government statistics, or industry associations.

- It’s often used when primary data isn’t available or is of low quality.

- For instance, if you can’t get detailed data from a supplier, you might use industry averages or reports on similar activities, and this is considered secondary data.

Choosing Data Based on Business Goals and Significance:

- You should pick data depending on your company’s business goals, the importance of scope 3 activities, and the availability and quality of data.

- High priority activities should ideally be supported with high-quality primary data. For instance, if your focus is reducing emissions in specific parts of your value chain, you should get detailed data from suppliers involved in those activities.

- In cases where primary data isn’t available or isn’t of good quality, secondary data could be more reliable. For example, if a supplier can’t provide data, or if available secondary data is better than poor-quality primary data, you may opt for secondary data.

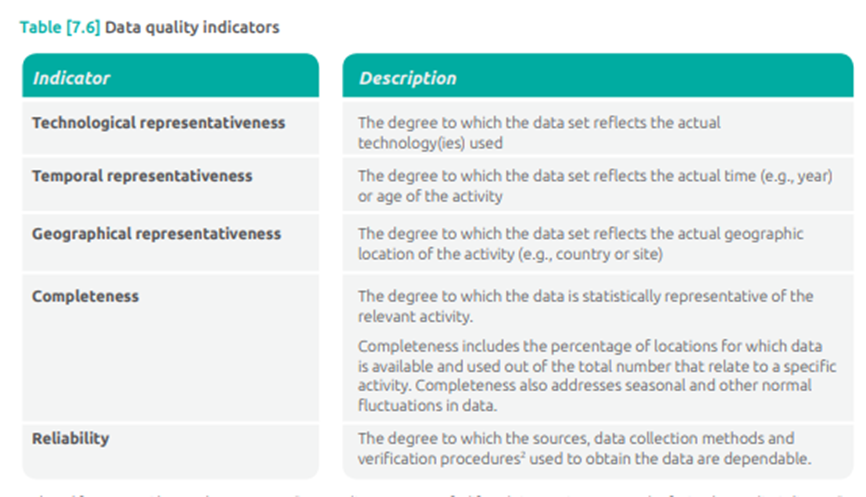

Data Quality Indicators:

- When selecting data sources, you should consider data quality indicators like how well the data represents the technology, time, and geography of the emissions activity, the completeness of the data, and the reliability of the measurements.

- For the best data quality, choose data that are most representative, complete, and reliable. For example, use data that closely match the technology and timeframe of the activity you’re estimating emissions for.

- This helps ensure that your emissions inventory is both accurate and relevant, which is vital for meeting your goals and supporting decision-making.

Challenges for Scope 3 Data:

- Collecting data for scope 3 emissions can be more challenging than for activities under your direct control.

- Challenges include relying on partners for data, having less influence over data collection, needing a broader range of secondary data, and having to make more assumptions and use modeling.

- These challenges might result in more uncertainty in your scope 3 calculations, but some level of uncertainty is acceptable as long as your data quality is good enough to meet your goals.

Data Management Plan:

- It’s a good practice to create a data management plan that documents your greenhouse gas inventory process, including quality assurance and control procedures.

- This plan helps you maintain data quality from the beginning of the inventory process through to the final reporting.

Guidance for collecting primary data

Why Collect Data from Suppliers:

- To accurately calculate your company’s scope 3 emissions, you often need detailed data from suppliers and other partners in your value chain.

- These data can include things like how much energy is used, how many emissions are produced, and where they come from.

Obtaining Primary Data:

- Primary data is the most accurate and specific kind of data you can get, and it’s gathered directly from your suppliers or partners.

- You can collect it in various ways, like reading meters, checking purchase records, analyzing utility bills, using engineering models, or monitoring processes directly.

Identifying Relevant Suppliers:

- Companies should identify key suppliers, especially the ones involved in high-priority scope 3 activities.

- For instance, if you’re focused on reducing emissions from shipping, you’d want data from the suppliers involved in this activity.

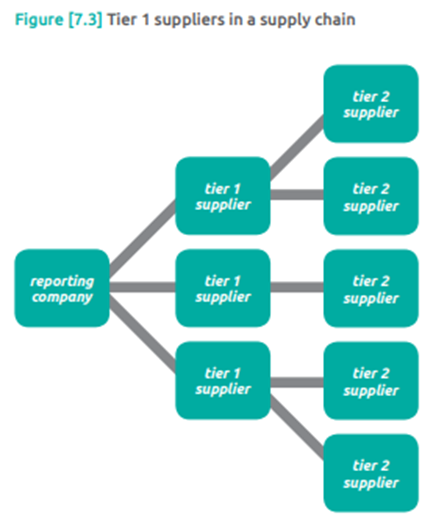

Working with Tier 1 Suppliers:

- Companies typically start by engaging with their tier 1 suppliers, which are the suppliers with whom they have formal agreements. These suppliers have contractual obligations.

- The idea is to work closely with those who have the most direct influence on your emissions.

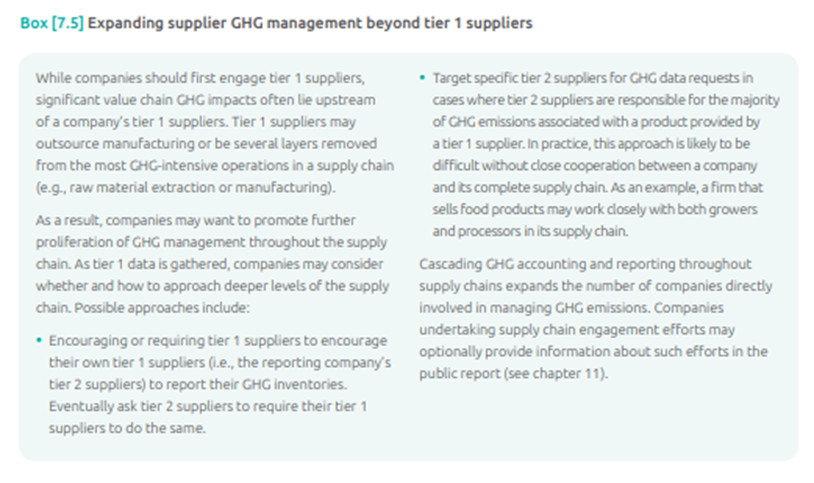

Expanding to Tier 2 Suppliers When Relevant:

- Sometimes, it’s important to go beyond tier 1 and work with tier 2 suppliers, who supply to your tier 1 suppliers.

- Your data collection may depend on how your tier 1 suppliers are getting their goods or services from tier 2 suppliers.

Selecting Suppliers for Data Collection:

- You might decide to collect data from all tier 1 suppliers, or you might focus on the ones that contribute significantly to your spending or activities.

- This decision might vary depending on your company’s policies and priorities.

Requesting Data from Suppliers:

- When you engage with suppliers, you might send them questionnaires to collect the data you need.

- The data you request could include product-specific greenhouse gas emissions, scope 1 and 2 emissions for a particular year, and the supplier’s upstream scope 3 emissions, if applicable.

- You’d also ask about the methodologies they use to calculate emissions, whether the data is verified, and any other relevant information.

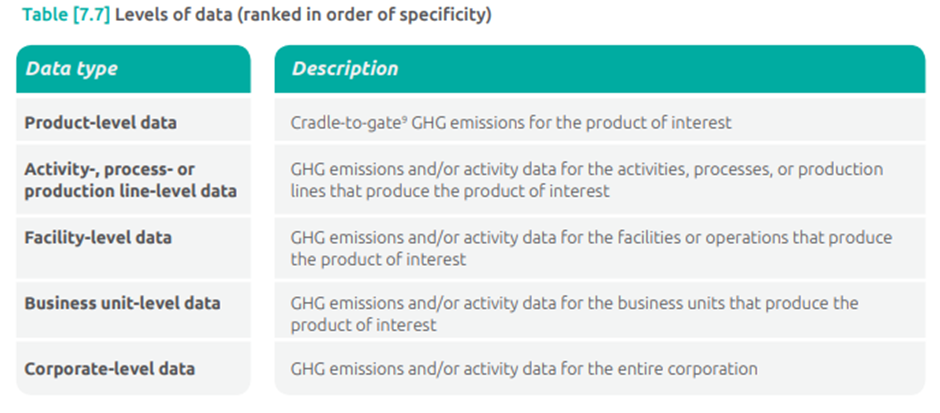

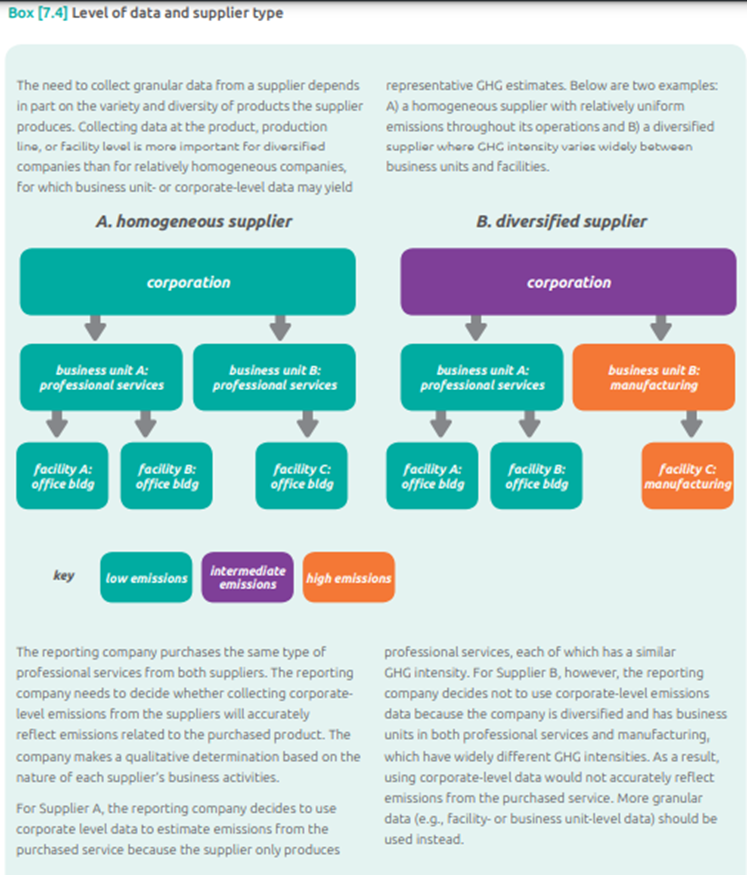

Levels of Data Detail:

- You should aim to get data at the most detailed level possible to avoid having to allocate emissions later. Product-specific data is the most precise, but sometimes, activity-, process-, or production line-level data might be what’s available.

Evaluating Data Quality:

- When working with suppliers, you need to assess the quality of the data they provide. You can use data quality indicators such as how well it represents their activities, its completeness, and its reliability.

- It’s a good practice for suppliers to explain their data sources and the quality of their data. They may even get their data verified by a third party to ensure accuracy.

- You should use these indicators to evaluate the quality of your suppliers’ data.

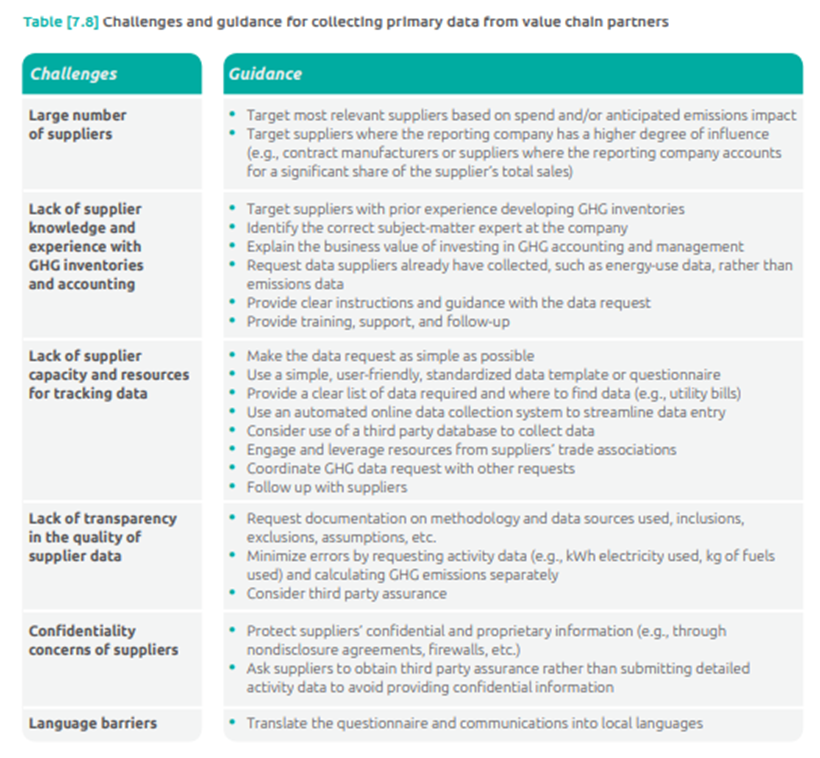

Overcoming Challenges:

- Collecting data from suppliers can be challenging due to various reasons, like suppliers’ inability to provide data or the data being of low quality.

- In such cases, you can encourage your suppliers to improve their data quality and share your efforts to encourage others to provide better data.

Guidance for collecting secondary data and filling data gaps

Collecting Secondary Data:

- Secondary data are sources of information you can use to estimate emissions data when you don’t have primary data from suppliers or partners.

- When using secondary data, prioritize databases and publications that are well-recognized internationally or provided by national governments. Peer-reviewed sources are also reliable.

- Use data-quality indicators, such as how well it represents your company’s activities in terms of technology, time, and location, and how complete and reliable it is.

Assessing Data Quality:

- To evaluate data quality, apply the data-quality indicators mentioned above. This helps you ensure that the secondary data you’re using is the best match for your company’s specific activities.

Proxy Data for Filling Data Gaps:

- If you can’t find data of good enough quality for certain activities, you might use proxy data as a substitute. Proxy data is information from a similar activity that stands in for the data you don’t have.

- Proxy data can be adjusted, scaled up, or customized to be more like the specific activity you’re trying to estimate.

Examples of Using Proxy Data:

- Let’s say you need emissions data for electricity use in Moldova, but you can’t find specific data for Moldova. You do have data for Ukraine. You could use the electricity emissions data from Ukraine as a proxy for Moldova since the two regions might have similar characteristics.

- Imagine you’re trying to collect data for a specific product category, and you have data for 80% of your production. For the remaining 20% where you don’t have data, you might assume it’s similar to the 80% you know about and use a simple calculation to estimate emissions for the entire category. This method is called linear extrapolation.

Improving data quality over time

1. Initial Data Collection:

- When you start collecting data for your emissions inventory, you may have to use data of relatively low quality because there might be limitations in terms of data availability.

2. Apply Data Quality Indicators:

- During this initial data collection phase, it’s important to apply data quality indicators, which are criteria to evaluate the quality of data (e.g., how well it represents your company’s activities, how complete and reliable it is).

3. Assess Data Quality:

- After collecting this initial data, you should assess its quality using the data quality indicators you applied. This helps you understand how accurate, complete, and reliable your data is.

4. Review and Iterate:

- The process of collecting data, assessing data quality, and improving data quality is an ongoing, iterative process.

- You will periodically review and reassess the quality of data you’ve collected. This involves reapplying the same data quality assessment approach to see if there have been improvements.

5. Seek Improvements:

- As you continue to work on your emissions inventory, you should aim to replace lower quality data with higher quality data as it becomes available.

- You should prioritize improving data quality for activities that have relatively low-quality data (as determined by the data quality indicators) and activities that result in relatively high emissions.

6. Transparency and Reporting:

- Companies are required to be transparent about the data quality of their reported scope 3 emissions data. This ensures that others can understand the quality of the data and avoid misinterpretation.

7. Recalculating Emissions:

- When you make significant improvements in data quality over time, especially in your base year emissions data, there may be a need to recalculate and update your emissions inventory to reflect these improvements. This ensures that your emissions reporting is as accurate and reliable as possible.

Endnotes for collecting data

- Data Quality Comparison:

This point suggests that sometimes data collected from a secondary source (like a reputable database or publication) for a specific activity may be of better quality than data provided directly by a supplier. This can happen because secondary sources often use large-scale, comprehensive data collection methods.

- Verification:

Verification is the process of checking and confirming the accuracy and reliability of data. It can be done in various ways, such as on-site inspections, reviewing calculations, conducting mass balance checks, or cross-referencing data with other sources. For example, if a supplier claims to have reduced emissions, a verification process can confirm if that reduction is accurate.

- Verification (Again):

This point reiterates that verification can take several forms, such as on-site inspections or reviewing calculations. It’s an important part of ensuring data accuracy.

- Data Quality Scoring:

When assessing data quality, if emissions data is calculated based on actual measurements (like directly measuring inputs), it’s considered of high quality. However, if calculations involve assumptions or estimates, the data quality score may be rated as ‘Good’ or ‘Fair’ to reflect the reliance on assumptions.

- Supplier Emissions Data:

This point explains that when suppliers provide emissions data, it should include various greenhouse gases like CO2, CH4, N2O, HFCs, PFCs, and SF6. These emissions can be aggregated into units of carbon dioxide equivalent, rather than listing them separately.

- Data Collection Period:

Suppliers may report their emissions data on different timeframes, such as fiscal years or calendar years. It’s recommended that reporting companies adjust or collect this data to align with a consistent 12-month period for consistency in reporting.

- Consistency in Data Sources:

Companies are encouraged to use the same sources of emission factors and Global Warming Potential (GWP) values across their suppliers. This ensures consistency in the methods used to calculate emissions.

- Threshold for Data Collection:

Companies may set a threshold, such as 80%, to determine which suppliers they collect emissions data from. In this case, it means that if a supplier contributes to 80% or more of a company’s activities and spending, they should collect data from that supplier. However, companies can define their own threshold, which can be adjusted over time.

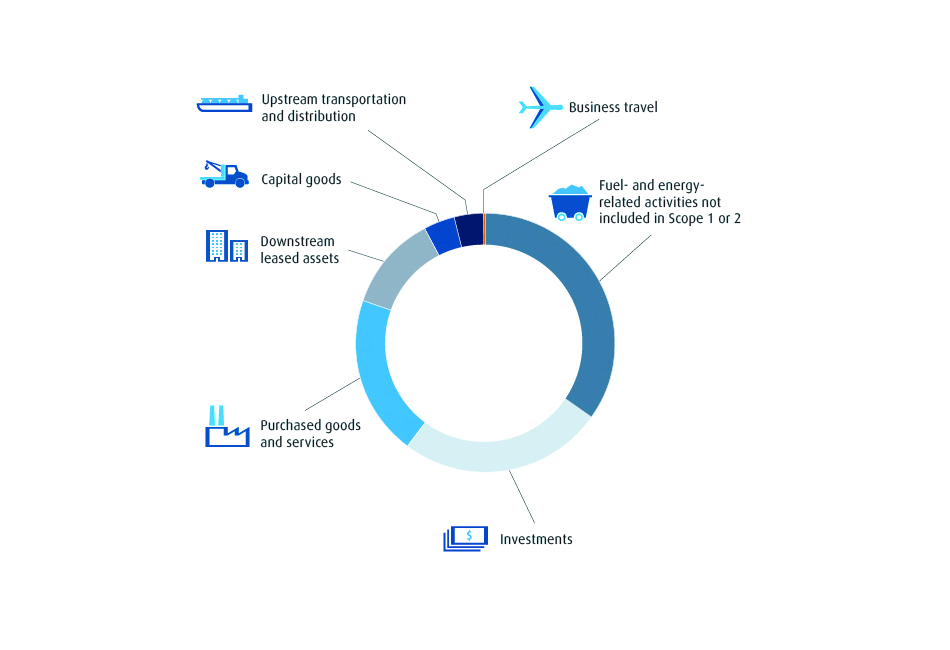

- Cradle-to-Gate Emissions:

Cradle-to-gate emissions include all emissions that occur in the life cycle of products purchased by a company, up to the point when the products are received by the company. It excludes emissions from sources that the company owns or controls.