Why Understanding Product Life Cycles Matters Today

Over the past few decades, environmental awareness has expanded far beyond governments and environmental organizations. Businesses, regulators, investors, and even everyday consumers now want to understand how products affect the environment—not just during use, but across their entire journey.

Today, questions such as “Where do raw materials come from?”, “How much energy is used in production?”, and “What happens after disposal?” are becoming central to sustainability discussions.

This growing demand for environmental transparency has led to the development of structured scientific methods that help organizations:

Clearly understand environmental impacts

Measure impacts using standardized and credible approaches

Identify opportunities to reduce environmental damage

Support sustainability strategies and regulatory compliance

One of the most globally recognized and scientifically reliable methods developed for this purpose is Life Cycle Assessment (LCA).

What is Life Cycle Assessment (LCA)?

Environmental impact does not occur at just one stage of a product’s journey. Instead, it is distributed across multiple stages, including Life Cycle Assessment (LCA) is a systematic method used to evaluate the environmental impacts associated with a product, process, or service throughout its entire life cycle.

Instead of focusing on a single stage, LCA examines every phase of a product’s existence, including:

Raw Material Extraction – Collecting natural resources required for production

Manufacturing and Production – Converting raw materials into finished goods

Transportation and Distribution – Moving materials and products through the supply chain

Product Use – Environmental impacts during usage

End-of-Life Treatment – Waste handling and treatment

Recycling and Recovery – Reuse of materials when possible

Final Disposal – Landfill or incineration when recovery is not feasible

This comprehensive approach is commonly known as the cradle-to-grave perspective, meaning environmental evaluation begins at resource extraction and continues until final disposal.

Real-World Example

Consider a plastic water bottle. At first glance, its environmental impact may appear limited to waste generation after use. However, an LCA study evaluates impacts across multiple stages, including:

Oil extraction required to produce plastic

Energy consumption during manufacturing

Emissions generated during transportation

Environmental effects of recycling or disposal

This broader perspective helps organizations identify where the greatest environmental impacts occur and where improvement efforts should be focused.

Why Organizations Use LCA

Although LCA originated as a research tool, it has evolved into a powerful decision-making framework used across industries, governments, and sustainability initiatives.

1. Improving Environmental Performance

LCA helps organizations identify environmental “hotspots” within their operations and supply chains. These insights allow companies to:

Reduce emissions and resource consumption

Improve production processes

Design environmentally responsible products

Optimize supply chain sustainability

For example, an electronics manufacturer might discover that most environmental impacts occur during raw material extraction rather than assembly. This insight could encourage the adoption of more sustainable sourcing practices.

2. Supporting Strategic Decision-Making

LCA provides data-driven environmental insights that help organizations:

Develop sustainability strategies

Design environmentally responsible policies

Set measurable environmental goals

Evaluate product design alternatives

Governments and non-governmental organizations also rely on LCA to guide environmental policy and sustainability programs.

3. Establishing Environmental Performance Indicators

LCA supports the identification and measurement of key environmental indicators such as:

Carbon footprint

Water usage

Resource depletion

Pollution potential

These indicators help organizations track sustainability performance and improvement progress.

4. Strengthening Sustainability Communication

LCA supports credible environmental communication through initiatives such as:

Eco-labels and green certifications

Environmental Product Declarations (EPDs)

Sustainability and ESG reporting

By providing scientifically backed environmental data, LCA improves transparency and stakeholder trust.

ISO Standards Governing Life Cycle Assessment

To ensure consistency and credibility across industries, LCA studies follow internationally recognized ISO standards.

ISO 14040 – Principles and Framework

ISO 14040 establishes the conceptual structure of LCA. It defines:

-

Core LCA principles

-

Study structure and phases

-

Relationships between different assessment stages

-

Requirements for transparency and scientific reliability

However, ISO 14040 focuses on the conceptual framework rather than technical calculations.

ISO 14044 – Technical Requirements and Implementation

ISO 14044 complements ISO 14040 by providing detailed technical guidance on:

-

Data collection methods

-

Environmental impact calculation procedures

-

Reporting and documentation requirements

-

Critical review processes

Together, ISO 14040 and ISO 14044 form the global methodological foundation for Life Cycle Assessment.

The Four Phases of Life Cycle Assessment

Every LCA study follows four interconnected and iterative phases.

Phase 1: Goal and Scope Definition

This phase establishes the foundation of the assessment by defining:

The purpose of the study

The product or system being analyzed

The intended audience

System boundaries (what is included and excluded)

The level of detail required

A key concept introduced in this phase is the functional unit, which provides a measurable reference point for comparison.

For example, instead of comparing packaging materials directly, an LCA may evaluate them based on:

“Packaging required to safely deliver 1,000 liters of beverage.”

This ensures fair and consistent environmental comparisons.

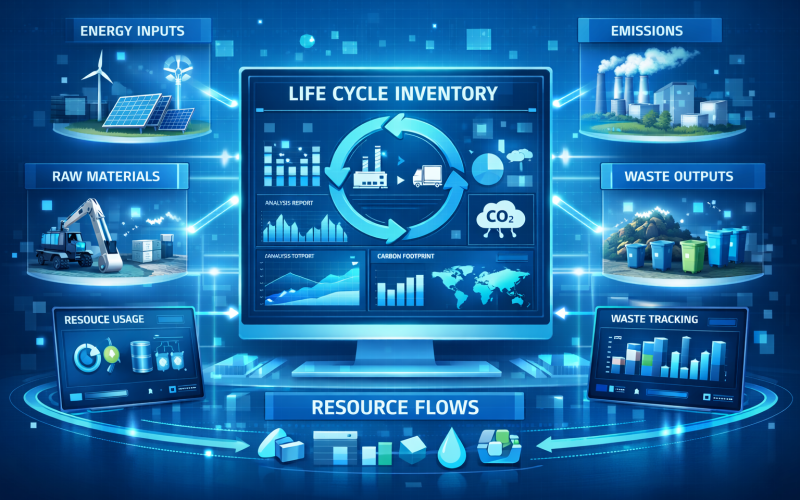

Phase 2: Life Cycle Inventory Analysis (LCI)

The inventory phase involves collecting and quantifying environmental data related to the product system.

LCI focuses on identifying:

Inputs

Raw materials

Energy consumption

Water usage

Outputs

Emissions to air, water, and soil

Waste and by-products

LCI essentially answers:

“What resources are consumed, and what environmental outputs are generated?”

Phase 3: Life Cycle Impact Assessment (LCIA)

LCIA evaluates the environmental significance of inventory data by translating raw inputs and outputs into environmental impact categories such as:

Climate change

Resource depletion

Pollution

Human and ecosystem health impacts

This phase answers:

“How do these environmental flows affect the environment?”

LCIA typically involves two mandatory steps:

Classification (assigning environmental flows to impact categories)

Characterization (quantifying impacts using scientific models)

Optional steps such as normalization, grouping, and weighting may also be applied.

Phase 4: Life Cycle Interpretation

Interpretation is the final analytical phase where results are:

Evaluated for reliability and consistency

Summarized into conclusions

Used to identify improvement opportunities

Translated into actionable sustainability recommendations

Importantly, LCA is an iterative process. Findings in later phases may require revisiting earlier stages to refine data or assumptions.

Core Principles That Make LCA Scientifically Reliable

LCA is guided by several core principles that ensure scientific reliability and meaningful results.

Life Cycle Perspective

LCA evaluates environmental impacts across the entire product life cycle to prevent environmental burden shifting between stages.

Environmental Focus

LCA primarily evaluates environmental impacts. Economic and social impacts are typically assessed using complementary tools such as:

Life Cycle Costing (LCC)

Social Life Cycle Assessment (S-LCA)

Relative Measurement

All results are measured relative to a defined functional unit, ensuring consistent comparison between alternatives.

Transparency

LCA requires clear documentation of data sources, assumptions, modelling approaches, and limitations.

Scientific Integrity

Whenever possible, LCA relies on natural science data. Any value-based decisions must be clearly justified and documented.

Understanding Product Systems in LCA

A product system represents the entire network of processes required to deliver a product or service. These systems are divided into smaller components known as unit processes, such as manufacturing, transportation, or recycling.

Types of Flows in LCA

Elementary Flows – Exchanges between the product system and the natural environment

Intermediate Flows – Materials transferred between production processes

Product Flows – Reusable or recyclable materials

Breaking product systems into unit processes improves data accuracy and environmental traceability.

Reporting in Life Cycle AssessmenT

Reporting is a critical component of LCA that ensures environmental results are transparent, credible, and useful for decision-making.

A complete LCA report must clearly explain:

What was studied

Why the study was conducted

How the study was performed

What the results mean

LCA reporting must also disclose:

Methodologies and assumptions

Data sources and quality

Environmental indicators and results

Study limitations and uncertainties

The Importance of Data Quality

Reliable LCA results depend heavily on data quality. ISO standards require evaluation of data across multiple dimensions:

Temporal relevance

Geographic relevance

Technological representativeness

Completeness

Consistency

Transparent data quality reporting allows stakeholders to assess confidence in results.

Critical Review: Ensuring Scientific Credibility

A critical review is an independent evaluation of an LCA study that verifies compliance with ISO standards and ensures methodological accuracy.

Critical review helps:

Improve scientific reliability

Increase stakeholder confidence

Prevent misuse of environmental results

Strengthen credibility of sustainability claims

When LCA results are used for public product comparisons, critical review becomes mandatory.

Practical Applications of LCA

LCA supports environmental decision-making across multiple industries and sectors.

Environmental Management Systems

LCA supports standards such as ISO 14001 by helping organizations identify environmental impacts and improvement opportunities.

Environmental Labels and Product Declarations

LCA forms the scientific basis for eco-labels and Environmental Product Declarations (EPDs), enabling transparent product environmental performance communication.

Sustainable Product Design

Design teams use LCA to evaluate alternative materials, manufacturing methods, and product lifecycle strategies.

Greenhouse Gas Accounting

LCA supports greenhouse gas reporting frameworks, particularly for value chain and Scope 3 emissions management.

Full LCA vs Partial Life Cycle Studies

Not all studies evaluate the entire life cycle. Common approaches include:

-

Cradle-to-Gate – From raw material extraction to product manufacturing

-

Gate-to-Gate – Assessment of a single production process

-

Stage-Specific Studies – Focus on selected lifecycle phases

Even partial studies must follow core ISO principles such as transparency and data quality.

Attributional vs Consequential LCA

Two major analytical approaches exist in LCA.

Attributional LCA

This approach describes the environmental profile of a product based on existing production systems. It is commonly used for carbon footprinting and environmental reporting.

Consequential LCA

This approach evaluates environmental consequences of future decisions or system changes. It is widely used in policy analysis and strategic planning.

Limitations of Life Cycle Assessment

Despite its strengths, LCA has certain limitations:

-

Results represent potential environmental impacts rather than exact real-world outcomes

-

Data availability and modelling uncertainties may affect results

-

LCA does not directly evaluate economic or social sustainability

Recognizing these limitations ensures responsible interpretation and application of results.

The Strategic Value of Life Cycle Assessment

Life Cycle Assessment has evolved into one of the most powerful tools for sustainability decision-making. Its ability to evaluate environmental impacts across entire product life cycles makes it essential for:

-

Sustainable product design

-

Supply chain optimization

-

Climate strategy development

-

Regulatory compliance

-

ESG reporting and transparency

Even when organizations do not conduct full LCA studies, adopting life cycle thinking significantly improves environmental decision-making.

Conclusion

As environmental responsibility becomes central to global business and policy frameworks, organizations need reliable and scientifically grounded methods to evaluate environmental performance. Life Cycle Assessment provides this foundation by enabling comprehensive evaluation of environmental impacts across entire product life cycles.

By combining standardized methodology, scientific credibility, and strategic flexibility, LCA allows organizations to move beyond surface-level sustainability efforts toward measurable and meaningful environmental improvement.

In an increasingly sustainability-driven world, Life Cycle Assessment is not just a technical tool—it is a critical framework for building environmentally responsible and future-ready systems.